- measurement of samples or parts batches (once or on a regular basis);

- consultations on methods and best tools to measure products or certain parameters;

- assistance in development of a measurement software for users of ZEISS coordinate measuring equipment;

- comparison of measurement outcomes with the results obtained with different equipment;

- professional development, training and workshops on how to operate ZEISS coordinate measuring equipment considering special features of the equipment and specialized requirements.

Contact Demonstration Centre experts for a consultation >>

Demonstration Centre ZEISS Russia & CIS has the following equipment for quality control:

The next generation CONTURA multisensor coordinate measuring machine has a measuring accuracy of 1.6 µm and is equipped with a rotary table and test volume of 900×1200×800 mm.

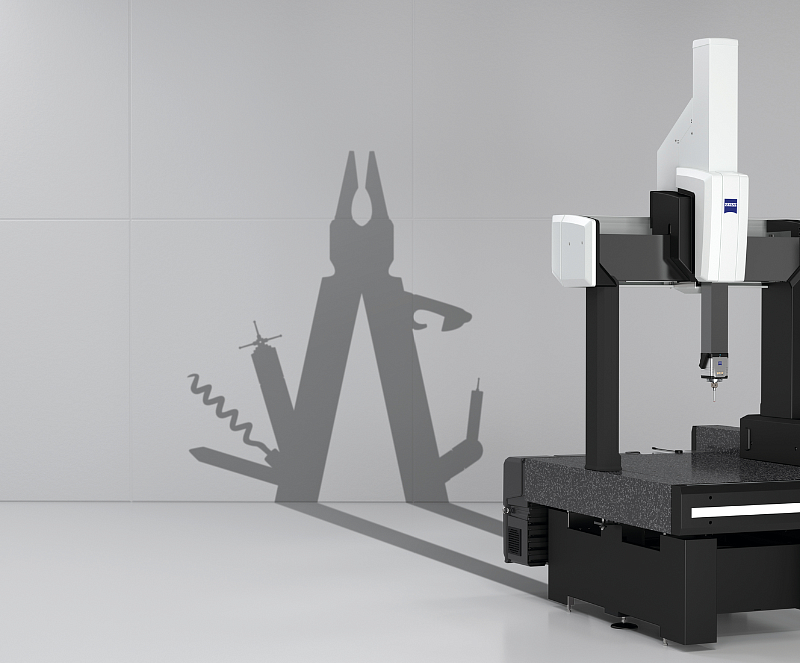

Accessories of the coordinate measuring machine enables you to perform the widest range of measurements including specific tasks:

- measurement of gear wheels of all types including conic, screw type and gear tools;

- measurement of complex curved surfaces, such as molds and stamps;

- measurement of turbine parts;

- measurement of thread parameters such as accumulated pitch variation, profile deviations and screw drives parameters;

- reverse engineering of devices.

Thanks to the unique optical system with auto-focus function it allows for three-dimensional optical measurements of device geometry with a measuring accuracy of 2.4 µm when a surface can be easily damaged during tactile measurement.

A unique 2D measuring device having a lens with a field of view of 100x100 mm. It allows for one-shot measurement of one or a several parts at the same time both under refracted and transmitted light with a measuring accuracy of 4 µm.

A universal system for a rapid and efficient digitization of surfaces and for analysing deviations from CAD-models in large parts. It is equipped with a laser scanner for a quick analysis of the entire surface of a device and with a hand probe to measure inaccessible internal components. Powerful software GOM Inspect provides for an immediate complete analysis of parts making it possible to compare deviations in relation to 3D СAD-model quickly and for derivation of linear dimensions, form and location tolerance.

The system is designed for 3D-optical measurement of precision devices with a tolerance up to 8 µm and allows for a quick collection of array of data with a high point density for maximum surface detail. The system provides for the following functionalities: — digitization and reverse engineering of parts; — analysis of deviations in relation to a CAD-model; — photogrammetry of parts or objects. For example, in designer tasks when you need to get a 3D-model with texture.

Please, complete the feedback form to get a preliminary quote of consultation price or cost of the services to measure samples. Enter a brief description of your task in the comment field.

Form actions